Year 3 Project - Modular High Value Manufacturing System

Abstract

With the introduction of Industry 4.0, many industries are starting to make the shift towards High Value Manufacturing (HVM). HVM systems are required to deal with components with high variation in order to meet ever-changing customer demands. This results in the need of systems with higher flexibility and modularity, as using standard large-scale manufacturing processes would be costly and inefficient.

Aim

The aim of this project is to present a novel solution that utilises Industry 4.0 technologies, such as Autonomous Mobile Robots (AMRs), a Cellular Omni-directional Conveyor (Omniveyor) system, Collaborative Robotics (Cobots) and the Robotics Operating System (ROS). The system was built over the ROS framework and simulated in Gazebo.

My Role

My role within the team was as the Lead Developer and Navigation Systems Engineer. My main responsibilities included:

- Developing the main communication framework

- Setting-up a ROS workspace (custom script)

- Developing the Gazebo simulation environment

- Requirements Capture

- Designing the system architecture

Since I was the only one with ROS experience, I also took it upon myself to share my knowledge with the team in the form of introductions, tutorials and guidance.

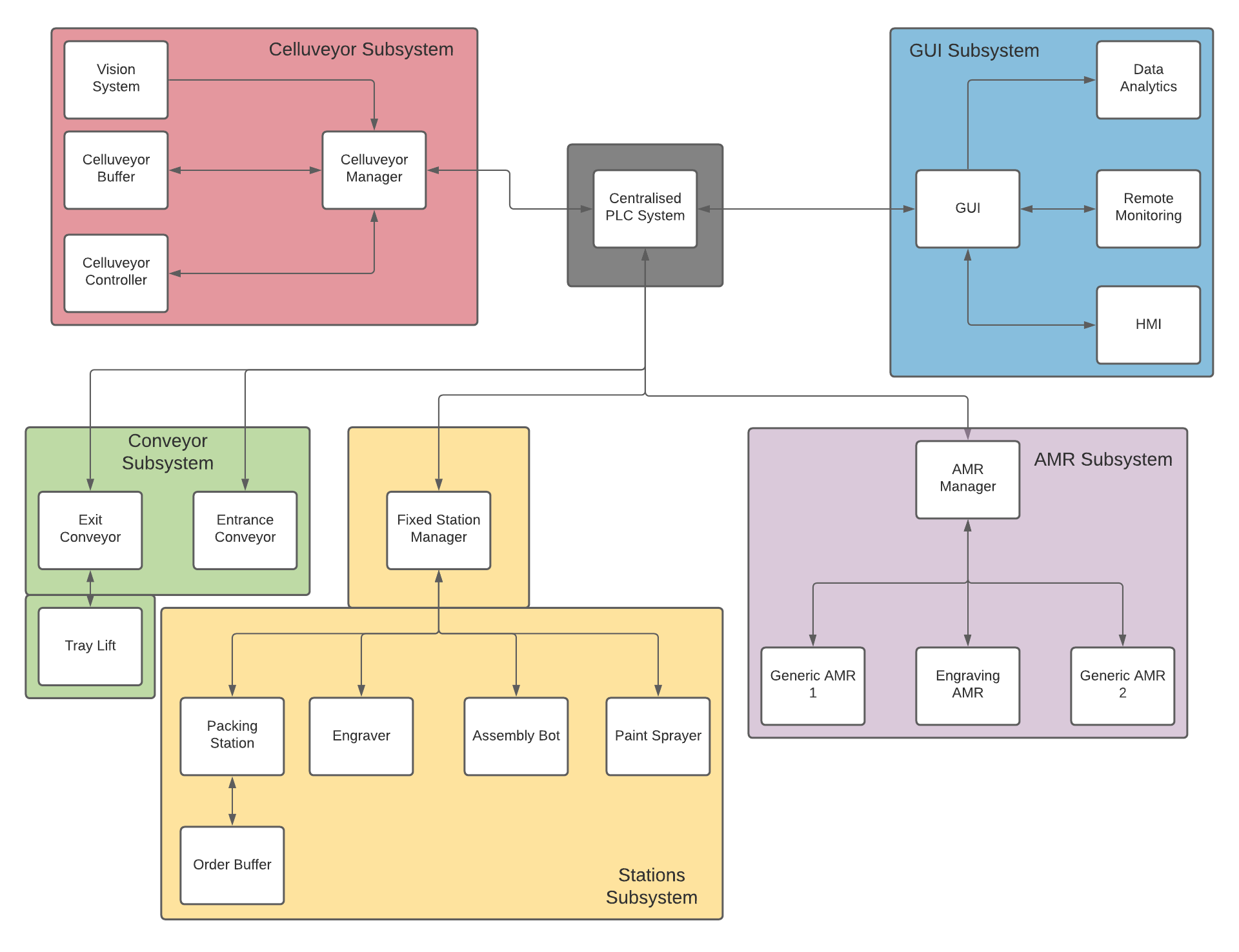

System Overview

The overall system was designed with modularity and flexibility as the main design requirements. To meet these requirements, the system was built upon an Omniveyor system that is capable of moving any component along a plane, where a traditional conveyor system is only capable of linear movement along a line. The Omniveyor subsystem is responsible for sending a component to one of the multiple stations built along the outer edge of the Omniveyor. There are two types of stations, Fixed and Modular. Fixed stations are stations with a robot or industrial process that requires a human to either physically move the machine or mount a different tool. The Modular stations, however, are built on AMRs that drive to a station depending on the required demand, for example if a certain set of components required engraving, multiple engraving AMRs could drive to the modular stations.

System Architecture